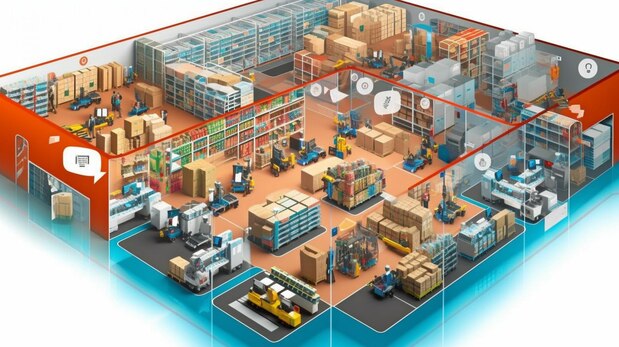

The design of a layout is crucial to running a small warehouse efficiently. To ensure your storage facility has a streamlined workflow, you need to select a layout suited to your business. This brings the question: What layout should you use, and how should you address the common challenges small warehouses face?

Follow this guide to learn what a warehouse layout is, the different types of layouts, and how to set up a warehouse.

What is a Small Warehouse Layout?

A small warehouse layout is a way to organize the things in a storage facility. This layout aims to improve the flow of products within your 1000 square feet or less warehouse. It does so by streamlining operations.

This layout should address the common issues that small warehouses have, such as:

- Inventory capacity is small.

- Storage is congested.

- Employees stumble into each other and equipment and stored products.

The Types of Warehouse Layouts

There are two major types of warehouse layout designs: Through Flow and U-shape. These types are categorized by their shape and the way products move through the warehouse.

1. Through Flow

Under the Through Flow type of layout, there are ‘Straight’ and ‘L-shape’. The main difference between the two is that Straight has its receiving and shipping docks on opposite ends of the warehouse. On the other hand, the L-shape layout has its docks on adjacent sides of the warehouse.

These two layouts have a lot more in common, such as providing more docking, storage, and sorting areas. Furthermore, you can move more products with these layouts.

However, building and maintaining these layouts require more space, labour, and capital.

2. U-Shape

The U-shape warehouse layout makes half a loop in the building. Both its receiving and shipping docks are on the same side. This gives this shape a very fast-moving lane and a slow one.

U-shape warehouses cut labour costs since the same workers and equipment can work on both docks. However, since the docking equipment, workers, and area are all shared, there is a risk of a bottleneck forming. This is because if one area becomes affected, both will be slowed down.

How to Create an Efficient Warehouse Layout

While you could use an existing layout, it is better to create your own warehouse setup project plan. Your unique design will specifically address your needs.

First, you need to have accurate measurements of the warehouse. You can measure your warehouse or find the details in its blueprints. Additionally, you should measure the amount, size, and weight of your products.

Now that you have all the figures you need, you can follow these steps to learn how to set up a warehouse.

1. Consider Your Needs

To have an efficient warehouse, you need to consider the needs of your warehouse. Ask yourself:

- Which equipment will efficiently move around my products?

- What kind of labour do I need, and how much can I afford?

- How long will each product have to remain at each stage?

2. Plan Your Product Flow

To figure out the number and types of lanes you need, visualize the stages your product goes through, from receiving to shipment. Imagine the most efficient way to get your product to the shipping dock. Meanwhile, keep in mind:

- Product quantity

- Number of steps from receiving to shipment

- The time each step takes

- The order of the steps

Furthermore, your warehouse needs a workflow that smoothly goes from one end of the warehouse to the other. There should be no backtracking; your main processing area should be in the middle.

3. Plan Different Areas

Next, plan the areas in your warehouse based on your inventory and the workflow. Consider these areas when setting up a warehouse:

- Receiving

- Storage

- Processing

- Packing

- Shipping

- Reception

- Dispatch Office

- Management Office

- Changing Rooms

- Bathrooms

While designing your layout, consider:

- The aisles should be wide enough for the inventory, equipment, and staff to pass safely.

- Your equipment also needs an area where you can store it and charge it.

- You need to take into account the stationary elements in your plans, such as stairs and bathrooms.

4. Plan Your Storage

Here, you need to plan how you will store your goods. You should consider the dimensions of your goods and how long they will stay in your warehouse.

Here are ways to store inventory in a warehouse:

- Floor Staking: This method involves putting a few pallets on top of each other and then stacking inventory on top of it. While this method is cheap, it is only suitable for non-perishables. Also, there is a limit to how high you can stack depending on the weight of the product and the durability of its packaging.

- Bins: You can store small items in bins. Bins can also be cheap and easy to move.

- Shelving: On light or heavy-duty shelves, you can store items of different dimensions. This method is cheap and adjustable.

- Pallet Racking: This method lets you store inventory on large racks meant for pallets. This is especially good for medium to heavy loads.

5. Test Your Layout and Get Feedback

Now that you know how to set up a warehouse, you need to refine your layout. You should train your staff so they can familiarize themselves with the workflow. You should do practice runs or even start using that layout. Then, ask for concerns and thoughts from your staff. Once you know where your layout fails and succeeds, you can make adjustments until you have an efficient layout.

Conclusion

Conclusively, setting up the right layout for a small warehouse requires a few considerations. A layout should efficiently take your products through the warehouse. The “Through Flow” layout is expensive, but you can use it to move large quantities of goods. On the other hand, the “U-shape” layout is a cost-efficient option as it offers workflows in a ‘U’ form, and their receiving and shipping docks are in the same area. However, this type of layout is prone to bottlenecks.

Ultimately, it is best to form your own design that suits your needs. While designing your layout, keep in mind the storage size, workflow, and the different areas you need. Once you have a layout, test out your warehouse layout ideas and refine them.